Looking Back: From Old Skills to Modern Times

In the past, India was famous for selling handmade goods before the British came. Important things that happened include the first try at making iron with charcoal in Tamil Nadu in 1830 and the start of the Tata Group in 1868. It was hard for industries to grow because of regressive policies, but they did get bigger during the two World Wars. After India became independent, the government focused on big and important industries through five-year plans and a set of rules in 1956. Then, the focus shifted to farming- related industries, and there was a lot of government control, which made it difficult to compete with other countries. In 1991, new rules (LPG reforms) opened up the market to businesses from other countries and allowed private companies to grow.Since 2014, the government has been trying hard with the ‘Make in India’ plan to make India a major place for manufacturing around the world. This is similar to the old ‘Swadeshi’ movement, which encouraged people to rely on Indian-made goods.

What's Happening Now: Growth with Ongoing Issues

How Big the Market Is and How Much It Could Grow: Big Goals Ahead

What Helps Growth and Government Support: Making Things Bigger

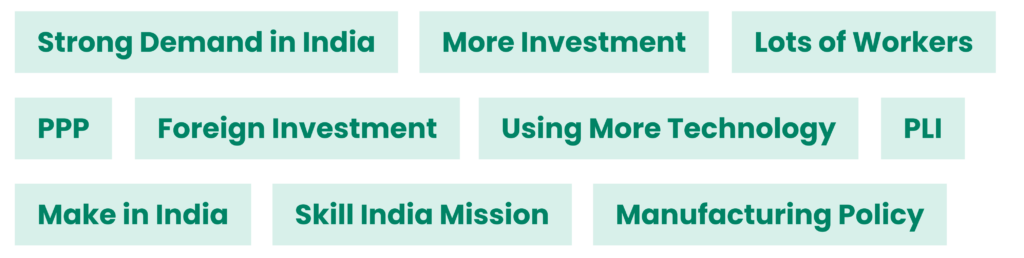

Manufacturing is growing in India because of several things:

- Strong Demand in India: A large and growing middle class is buying more things.

- More Investment: Foreign companies have invested US$ 165.1 billion in Indian manufacturing, which is 69% more than in the last ten years.

- Lots of Workers: India has a large number of people who can work, and their wages are relatively low.

- Partnerships Between Government and Private Companies (PPP): This helps build infrastructure and grow industries.

- Foreign Investment: More and more companies from other countries want to invest in India.

- Using More Technology: Moving towards digital ways of working and using advanced technologies (Industry 4.0) is making things more productive and efficient.

- Make in India: Started in 2014, this aims to turn India into a world leader in making, designing, and inventing things, covering 27 sectors. It has significantly reduced the number of mobile phones imported (by 85%). Make in India 2.0 focuses on 24 industries with high growth potential.

- Production-Linked Incentive (PLI) Schemes: These sector- specific incentives aim to boost domestic and foreign investments. The interim budget 2024 saw significant increases in PLI allocations for sectors like Semiconductors and Display Manufacturing Ecosystem (360% increase) and the Automobile sector (623% increase).

- Skill India Mission: Launched to train a large number of individuals in various skills, creating a qualified workforce to meet the demands of the manufacturing sector. Skill India Mission 2.0 focuses on demand-driven and outcome-based skilling.

- National Manufacturing Policy: This was introduced to increase the part that manufacturing plays in India’s economy and create more jobs. This includes creating National Investment and Manufacturing Zones (NIMZ’s), which are like industrial towns with easier approvals.

- Union Budget 2023-24 & Interim Budget 2024: These budgets have provided tax benefits for new manufacturing co- operative societies, extended the period for income tax benefits and carrying forward losses for startups, and increased turnover limits for presumptive taxation for MSMEs.

Challenges: A Big Task for Continued Growth

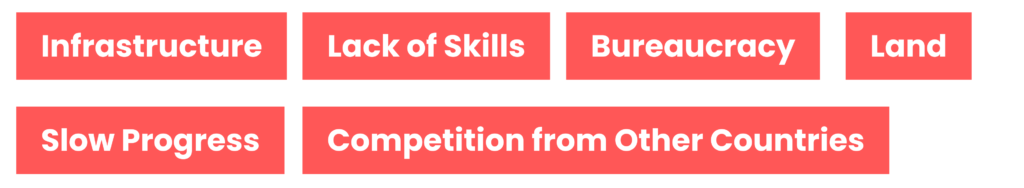

Despite the positive signs, India's manufacturing sector has many challenges:

- Not Enough Good Infrastructure: The World Bank’s Logistics Performance Index shows that India is not as good as many other Asian countries in this area. Problems like busy ports, bad roads, and unreliable electricity cause delays and increase costs. For example, it takes much longer for ships to unload and load in India compared to places like Singapore or China.

- Lack of Skills: According to the National Skill Development Corporation (NSDC), only about 5% of India’s workers have proper job training, compared to more than 50% in developed countries. This lack of skills makes it harder to improve productivity and come up with new ideas.

- Too Much Bureaucracy: The World Bank’s Ease of Doing Business rankings, although they have improved, still show that it’s complicated to deal with India’s rules. It can take many months, sometimes years, to get the necessary permissions and approvals.

- Getting Land: Disputes over land often cause projects to be delayed and cost more money. It takes much longer to get land in India compared to other developing countries.

- Competition from Other Countries: India’s manufactured goods face strong competition from countries where labour is cheaper and supply chains work better. India sells a much smaller percentage of its total production to other countries compared to many South-East Asian nations.

- Corruption and Slow Progress at Local Levels: The constant push to make it “easier to do business” will remain just words unless corruption at the local level is fixed and things are implemented more quickly.

Opportunities to Invest: A Key Area to Focus On

From the Managing Partner's desk

Gaurav VK Singhvi, Managing Partner, Avinya VC

The future of manufacturing in India looks very bright. India is definitely on its way to becoming a major global manufacturing hub, with the potential to sell US$ 1 trillion worth of goods to other countries by 2030 and significantly contribute to the overall goal of US$ 2 trillion in total exports.

Government support, increasing investments, a strong market in India, and a growing focus on technology and skills provide a strong base for continued growth and better competition with other countries.

However, achieving this potential depends on our ability to solve the underlying problems. We need more than just announcements; we need the government to put its plans into action effectively and efficiently. The time for just talking about it is over. We need clear action and a practical approach to unlock the real potential of India’s manufacturing sector.